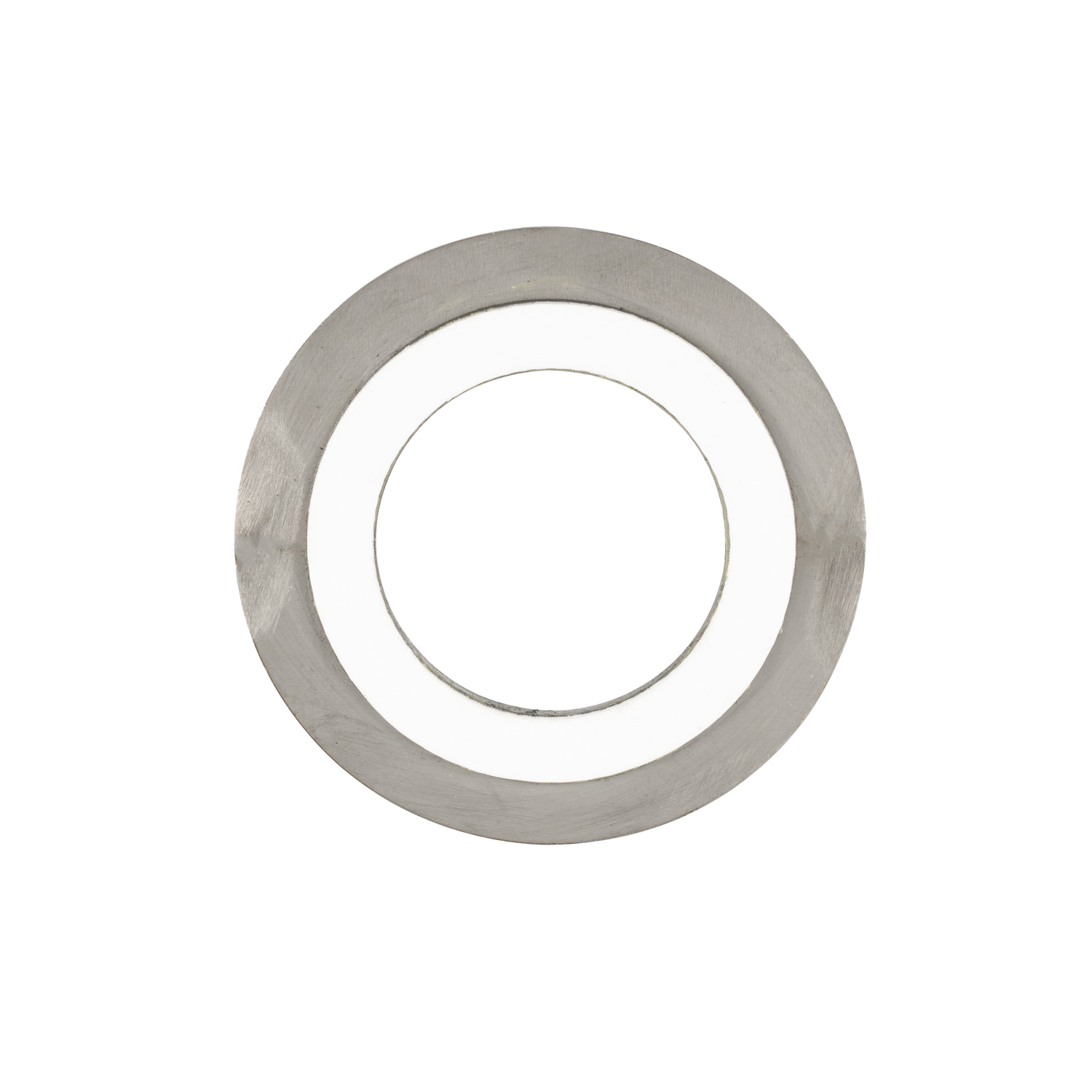

Kamprofile (Serrated) gasket is mechanically made from integral metal. Groove of concentric circles by processing with professional equipments. It can be better sealed then the general metallic flat gasket. It is suitable for use on the flange pipe of high pressure and high temperature.

| Availability: | |

|---|---|

| Quantity: | |

gasket factor | m=4.25 |

pressure | ≤25MPa |

temperature | -196℃-650℃(≤450℃ in oxidant) |

minimum pretightening sealing load | y=50MPa |

The DH-G-MG Metallic Kammprofile Gasket is a high-performance metal gasket featuring a corrugated (kammprofile) metal core and graphite/PTFE facing. Constructed from 316L stainless steel (standard) or Inconel 625 (high-temperature), it meets ASME B16.20, API 601, and ISO 22262-1 standards. Standard sizes cover DN15-DN2000 flanges (PN16-PN420), with custom profiles available for non-standard flanges; thickness ranges from 1.5mm-5.0mm (core + facing).

Temperature Range: 316L variant: -196℃ to +450℃; Inconel 625 variant: -200℃ to +650℃.

Pressure Capacity: Up to 45MPa (static), 30MPa (dynamic) – suitable for high-pressure vessel flanges.

Sealing Performance: Helium leak rate ≤ 1×10⁻⁹ Pa·m³/s (ISO 12747-2); effective on flange roughness up to Ra 1.6μm.

Facing Options:

Graphite facing: For high temp (up to 450℃), thermal conductivity 10 W/(m·K).

PTFE facing: For chemical resistance (acids, solvents), operating temp up to 260℃.

Structural Integrity: Corrugated profile provides 30% higher compression rebound than flat metal gaskets.

Oil & Gas: Wellhead flanges (40MPa), subsea pipeline connections (30MPa, -50℃).

Power Generation: Steam turbine flanges (450℃, 25MPa), nuclear auxiliary system valves.

Chemical Processing: High-pressure reactor flanges (35MPa, 300℃), autoclave doors.

Petrochemical: Hydrocracker flanges (400℃, 35MPa), amine treater vessels.

Graphite facing: Choose for temperatures > 260℃, thermal cycling applications, or when thermal conductivity is critical (e.g., steam lines).

PTFE facing: Choose for chemical service (acids, solvents), food/pharma applications (FDA-compliant), or to prevent flange adhesion.

Hybrid facing: Available for mixed service (e.g., 300℃ + chemical exposure).

Works with all standard flange types:

Raised face (RF): Optimal for PN16-PN100.

Ring type joint (RTJ): Use with Inconel core for PN160-PN420.

Flat face (FF): Requires PTFE facing and lower compression (10-15%).

Ensure flange hardness < core hardness (316L core: 180 HV; Inconel 625: 220 HV).

Address