DONHONSIL Supplies quality products which help solve most flange sealing and insulation problems also. Our insulation kits are typically used on offshore installations, seawater environments, chemical installations, oil refinery pipelines where the flange need to be properly to prevent leakage and also must be catholically insulated.

DONHONSIL Flange insulation kits are following standards ANSI 16.5 & API 605, other standards need to provide more specifications according to our requirements.

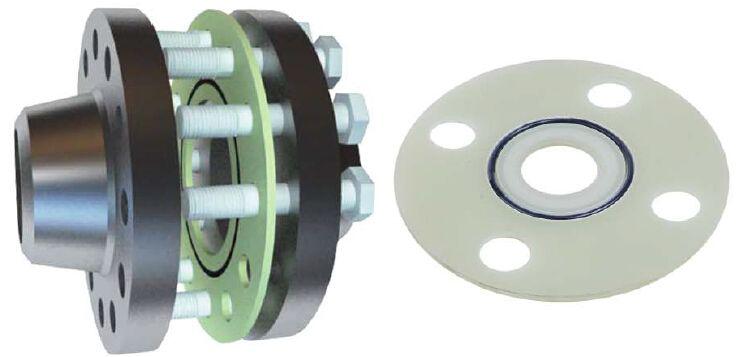

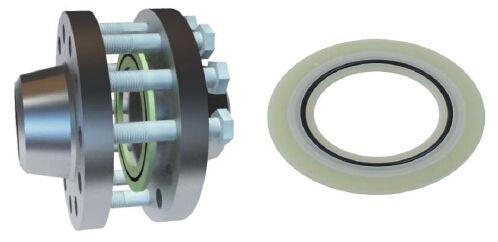

Flange insulation kits consist of an insulating gasket, some insulating sleeves and washers which are all correctly sized for the application and conveniently packaged to minimize the possibility of lost component parts during installation.

Insulating gaskets may be specified as “E” and “F” types while single, double or one-piece sleeve and washer sets are offered as options for varying degrees of electrical insulation between the flanges. In addition, a wide variety of material options exist for both insulating gaskets and sleeve and washer materials. The G-10 retainer and Mylar sleeve are recommended when the conditions allowed.

Insulation KIT Types:

Type E Gaskets:

Type “E” is a full face gasket with some outside diameter as the flange and precision cut bolt holes. This design facilitates proper alignment of the gasket during installation. This assembly minimizes the ingress of conductive foreign matter between the portions of the flanges outside the raise face and reduces the risk of bridging.

Type F Gaskets:

Type “F” gaskets are made of fit the raise face portion of the flange only. As there are no bolt holes in the “F” gaskets, the outside diameter of the gasket fit tightly into place assuring a well centered position.

Type D Gaskets:

Type “D” Gaskets are available for RTJ flanges, the common material is pheolic and basic type is oval. They are usually made to fit RTJ flanges of ASME B16.5. But in fact, the sealing gasket is an excellent alternative to “D” gaskets,because the sealing element can be positioned anywhere between the I.D. of the gasket and I.D. of the ring groove.

Insulation KIT Styles:

DH-S-NPSEAL sealing gaskets use a rectangular sealing element enclosed into a unique groove to seal and isolate all types of flanges. This kind gasket can provide theoretical near zero “m” and “y” factors resulting in effecting a positive seal without excessive bolt loads required with flat gaskets. Materials such as Teflon and Viton also can be Used as the sealing element, which increases the choice of material.

NPseal sealing gaskets are widely used for low and medium pressure, but in order to get much better sealing performance, for the pressure equal to or higher than ANSI 600#, please consider HPSEAL sealing gaskets first.

DH-S-HPSEAL insulating gasket utilizes a stainless steel core boned with high strength insulating laminate G10 or G11, which not only maintains the high strength of stainless steel, but also reaches an excellent insulation. It consists of a spring-energized Teflon seal which provides high confidence sealing and eliminates costly leaks. And the seal groove is cut into the stainless steel core, which can avoid leakage through the interval of two materials.

HPSEAL insulating gasket is designed to seal and insulate for very critical services. It can seal and insulate raised face flanges, full face flanges, and ring joint flanges at all pressures up to ANSI 2500# and API 15000#. While 316 grade of stainless steel is most commonly required as a core material, we can also offer more exotic materials such as Super Duplex, Hastelloy and Inconel.

DH-S-RFSEAL (Fire Safe) insulating gasket is API 6FB certified, which includes a PTFE spring-energized primary sealing element and a Mica secondary sealing element. It adds fire service capability to the standard RFSEAL design through the use of a secondary sealing element of high temperature resistant Mica, which can maintain a sealing performance while subject to a fire of 1500°F (815°C). Under this design, the PTFE spring-energized primary sealing element and Mica

secondary sealing element are both seated in the retainer of insulating laminate bonded to a stainless steel core, creating a fireproof insulating gasket.

Both seals of RFSEAL gasket have very good spring back, they require low bolt stress for the sealing. Second seal will be a backup seal under the normal environment, and it will work once the first seal failure during the fire.

Insulating Sleeves:

Our insulating sleeves are designed to easily fit over standard size flange bolts/studs within standard size bolt holes, and are used with separate insulating and steel washers. They are available for standard American bolt sizes from 1/2” (12.7mm) to 3-1/2” (88.9mm) as well as metric bolt sizes from 12mm and larger.

Insulating sleeves are available in the following materials:

• Mylar

• Phenolic

• Nomex®

• G-10 Epoxy Glass

• G-11 Epoxy Glass

• High Strength Mica

Insulating Washers:

Our insulating washers are designed to provide tough, positive isolation. They are available for bolt sizes from 1/2” (12.7mm) through 3-1/2” (88.9mm) and are made to fit over the insulating sleeves. Insulating washers are available in the following materials:

• High Strength Phenolic

• G-10 Epoxy Glass

• G-11 Epoxy Glass

• High Strength Mica

Spec | (F) Phenolic | G10 | G11 |

Dielectric Strength Volts/Mil | 500 | 550 | 550 |

Water Absoprtion % | 1.6 | 0.1 | 0.1 |

Operating Temp. ºF | -65~+220 | -320~+280 | -320~+349 |

Operating Temp. ºC | -54~+104 | -196~+138 | -196~+176 |

Compressive Strength ps | 25000 | 50000 | 50000 |

Tensile Strength psi | 20000 | 45000 | 43000 |

Steel Washers:

Usually, zinc plated steel washers are the standard steel washers for flange insulation kits, but as requirement, we also can offer other super materials, such as SS304, SS316, duplex, and so on.

Spec | Mylar | Nomax | G10 | G11 |

Dielectric Strength Volts/Mil | 4000 | 400 | 400 | 400 |

Water Absoprtion % | 0.8 | / | 0.1 | 0.1 |

Operating Temp. ºF | -79~+300 | -65~+450 | -320~+280 | -320~+349 |

Operating Temp. ºC | -59~+149 | -54~+232 | -196~+138 | -196~+176 |

Address