Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Have you ever wondered why a blown head gasket can lead to costly car repairs? This small yet essential part plays a vital role in maintaining engine health. When it fails, the consequences can be severe—engine damage, reduced performance, and expensive repairs.

In this article, we will explore what causes a blown head gasket. You will also learn how to prevent it and keep your engine running smoothly for longer.

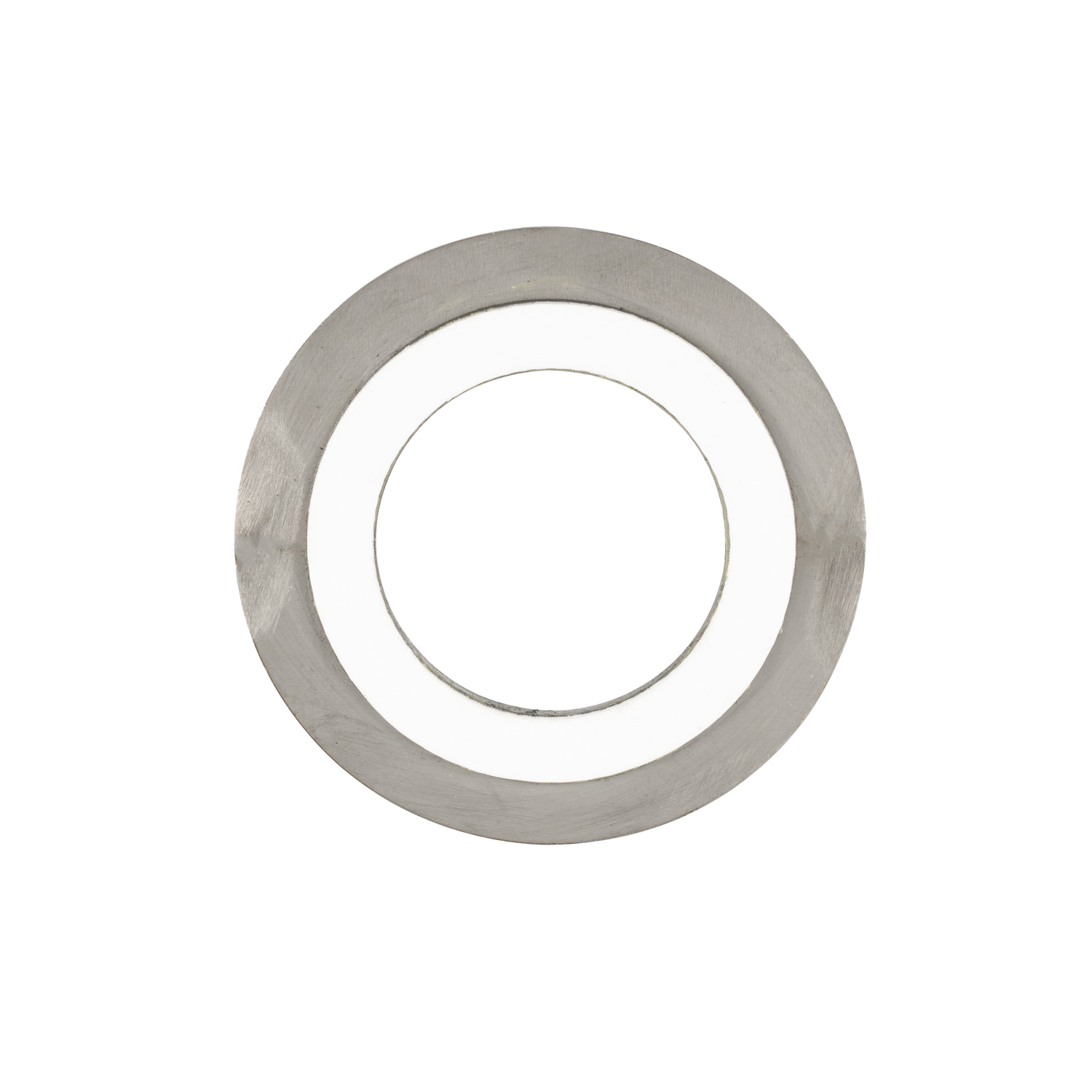

The head gasket is a large, flat seal located between the engine block and the cylinder head. This small but critical part has the important job of ensuring that the engine's coolant, oil, and combustion gases stay separate from one another. If the head gasket fails, it can result in the mixing of these fluids, causing severe engine damage.

The head gasket is subjected to extreme pressures and temperatures. It needs to withstand the intense heat generated during the combustion process while also maintaining a secure seal to prevent leaks. Without a properly functioning gasket, the engine would quickly overheat, lose power, or experience serious mechanical issues.

The head gasket serves several important functions:

● Sealing the Combustion Chamber: The gasket helps to keep the combustion chamber properly sealed. This is vital for maintaining engine compression, which is essential for efficient fuel combustion.

● Preventing Fluid Mixing: The gasket ensures that oil, coolant, and combustion gases do not mix. If coolant and oil mix, it can lead to severe engine issues, such as overheating and corrosion.

● Maintaining Engine Pressure: A properly functioning head gasket helps maintain the internal pressure needed for optimal engine performance. If it fails, it can cause a loss of compression, which leads to poor engine performance and misfires.

Function | Description |

Sealing the Combustion Chamber | Keeps the combustion chamber sealed, maintaining engine compression. |

Preventing Fluid Mixing | Ensures oil, coolant, and combustion gases stay separate to prevent damage. |

Maintaining Engine Pressure | Helps maintain internal pressure for smooth engine performance. |

One of the most common causes of a blown head gasket is overheating. When the engine operates at temperatures higher than its optimal range, the metal components of the engine block and cylinder head can warp. As the engine heats up, the metal expands, creating gaps where the gasket should seal. These gaps prevent the head gasket from sealing properly, which can lead to coolant leaking into the combustion chamber or combustion gases leaking into the cooling system.

Overheating is often caused by:

● Low Coolant Levels: If the coolant level in the radiator drops too low, the engine is unable to dissipate heat effectively, causing it to overheat. This can occur due to coolant leaks, a malfunctioning radiator, or not topping up coolant when needed.

● Faulty Radiator or Thermostat: If the radiator is clogged or the thermostat fails to regulate engine temperature, it can prevent the engine from staying cool, leading to overheating.

● Cooling System Failure: If the cooling system is not functioning properly, whether due to a damaged radiator hose or a faulty water pump, the engine will not receive the necessary coolant circulation, which can result in overheating.

Cause | Description |

Low Coolant Levels | Insufficient coolant prevents effective heat dissipation. |

Faulty Radiator or Thermostat | A clogged radiator or failing thermostat causes improper cooling. |

Cooling System Failure | Damaged hoses or faulty water pumps prevent coolant circulation. |

Tip: Keep coolant levels topped off and have your radiator and thermostat inspected regularly to avoid overheating. A proactive approach to cooling system maintenance can significantly reduce the risk of a blown head gasket.

High combustion pressure can also lead to head gasket failure. Pre-ignition and detonation are two key issues that can cause excessive pressure within the combustion chamber. Pre-ignition occurs when the air-fuel mixture in the cylinder ignites too early, creating excessive pressure before the piston completes its compression stroke. Detonation, or "knocking," occurs when the fuel mixture ignites too explosively, causing the engine to misfire.

These abnormal combustion conditions increase the pressure on the head gasket. If the gasket is unable to withstand this pressure, it can crack or blow. Other factors that contribute to high combustion pressure include:

● Incorrect Fuel Grade: Using lower-octane fuel than what is recommended for your vehicle can increase the likelihood of pre-ignition and detonation. This additional pressure can damage the head gasket over time.

● Carbon Buildup: Over time, carbon deposits can form in the combustion chamber, affecting the air-fuel mixture and leading to higher combustion pressures.

● Incorrect Ignition Timing: If the ignition timing is off, the spark plug can fire too early or too late, causing combustion problems that stress the head gasket.

Tip: Always use the correct fuel grade for your vehicle and check your ignition timing to prevent excessive combustion pressure. Proper fuel and ignition system maintenance can help extend the life of your head gasket.

Head gaskets are made from durable materials like metal and composite materials, but like any engine part, they will eventually wear out. Repeated exposure to high temperatures and pressures causes the gasket material to degrade over time. In older vehicles or those with a history of overheating, the head gasket is more likely to fail as it loses its ability to maintain a proper seal.

The constant expansion and contraction of the engine components, along with the stress placed on the gasket during normal engine operation, contribute to the gradual degradation of the gasket. As the gasket material breaks down, small cracks or holes can develop, leading to leaks. In some cases, the gasket may even split entirely, causing coolant or oil to leak into the combustion chamber.

Tip: Regularly inspect your head gasket for signs of wear, particularly if your car is older or has experienced overheating in the past. Catching small issues early can prevent major engine damage.

When the engine is rebuilt or repaired, it's crucial that the head bolts are torqued to the manufacturer’s specifications. If the bolts are too tight or too loose, the head gasket may not form a proper seal, leading to gasket failure. Incorrect torque can cause the gasket to be compressed unevenly, resulting in gaps where coolant or oil can leak through.

This issue is particularly common in vehicles that have undergone repairs or engine assembly without proper attention to torque specifications. A mechanic who does not follow the manufacturer’s recommended torque settings may inadvertently cause the gasket to fail prematurely.

As the engine operates, it generates a significant amount of heat. The engine block and cylinder head expand at different rates, causing stress on the head gasket. Over time, the constant exposure to high heat causes the gasket material to break down, leading to seal failure. As the gasket weakens, it becomes more susceptible to cracking or blowing.

In addition to heat, the mechanical forces generated by engine operation also contribute to head gasket wear. Each time the engine fires, pressure is applied to the gasket. Over time, this pressure causes the gasket to weaken. In high-performance or older engines, the additional stresses from engine operation and road vibrations can accelerate the wear process. These forces, combined with heat and pressure, eventually cause the gasket to fail.

One of the simplest yet most common causes of head gasket failure is neglecting regular maintenance, particularly for coolant and oil. If the coolant levels are too low, the engine may overheat, leading to gasket failure. Similarly, if the oil is not changed regularly, the engine may suffer from poor lubrication, which can increase friction and stress on the gasket.

Additionally, old or contaminated oil can mix with coolant, causing corrosion and damaging the gasket. Failing to maintain proper fluid levels can also cause the engine to operate under less-than-ideal conditions, putting additional strain on the head gasket.

The cooling system is vital to maintaining engine temperature and preventing overheating. Over time, components like the radiator, thermostat, and water pump can wear out or become clogged, affecting the flow of coolant through the engine. If the cooling system is not regularly inspected and maintained, it can cause the engine to overheat, leading to head gasket failure.

A blown head gasket often presents several warning signs. These may include:

● White Smoke from the Exhaust: This occurs when coolant leaks into the combustion chamber and is burned with the fuel. White smoke, often accompanied by a sweet smell, is a classic sign of a blown head gasket.

● Milky Oil: If coolant mixes with the oil, it creates a milky or frothy appearance. This can cause poor lubrication and serious engine damage if left unchecked.

● Loss of Power: A blown gasket can cause a loss of compression in the engine, resulting in poor engine performance, rough idling, or a decrease in power.

● Overheating: Even if the engine isn’t working hard, a blown head gasket can cause it to overheat due to coolant loss or improper coolant circulation.

Symptom | Description |

White Smoke from Exhaust | Coolant leaking into the combustion chamber, causing smoke. |

Milky Oil | Mixing of coolant and oil, appearing milky or frothy. |

Loss of Power | Decrease in engine performance, rough idling, or poor acceleration. |

Overheating | Engine temperature rising due to coolant loss or circulation issues. |

If you notice any of the symptoms of a blown head gasket, it’s crucial to address the problem immediately. Ignoring the issue can lead to more extensive damage, such as warped engine components or internal corrosion. By addressing the problem early, you can save yourself from expensive repairs and potentially prevent the need for a complete engine replacement.

The best way to prevent head gasket failure is by maintaining your vehicle properly. Regular maintenance, such as checking coolant levels, inspecting the radiator and thermostat, and changing the oil at recommended intervals, will help ensure the engine stays cool and operates efficiently.

The use of high-quality fluids, including oil and coolant, is essential for maintaining the integrity of the head gasket. Always use the fuel, oil, and coolant recommended by the manufacturer. Low-quality fluids can increase the likelihood of overheating or poor lubrication, which can lead to gasket failure.

A blown head gasket can cause significant engine damage and expensive repairs. Understanding the causes, like overheating, high combustion pressure, and poor maintenance, helps you take preventive measures. Regular maintenance, monitoring engine temperatures, and using high-quality fluids are key. DONHONSIL Gasket offers high-quality gaskets that ensure long-lasting engine performance, providing value through durable and reliable products.

A: A blown head gasket is mainly caused by overheating, high combustion pressure, poor maintenance, and using low-quality fluids. These factors weaken the gasket, leading to leaks or cracks.

A: Overheating causes metal components in the engine to expand, leading to warping and gaps where the head gasket should seal. This results in coolant or combustion gases leaking, which damages the engine.

A: Regular maintenance, including monitoring coolant levels, using high-quality fluids, and ensuring proper engine cooling, helps prevent head gasket failure and ensures your engine’s longevity.

A: It’s not advisable to drive with a blown head gasket, as it can cause further engine damage, overheating, and loss of power. It’s best to get it repaired as soon as possible.

A: Symptoms include white smoke from the exhaust, engine overheating, loss of power, and milky oil. If you notice these signs, it’s crucial to get your engine checked immediately.

Address