Views: 0 Author: Site Editor Publish Time: 2026-01-05 Origin: Site

Sealing materials are crucial for industrial systems, especially in high-temperature and high-pressure environments. As industries face more extreme conditions, reliable, durable sealing solutions are vital. One material that excels is the reinforced graphite gasket. This article explores its benefits, properties, and applications, showing why it is the go-to choice for demanding systems.

A reinforced graphite gasket is a type of sealing material composed of graphite, which is known for its excellent thermal and chemical resistance properties. To enhance its performance in demanding applications, the graphite is reinforced with additional materials such as metal inserts. This reinforcement helps the gasket withstand high pressure and temperature fluctuations, making it suitable for various industrial applications.

Unlike traditional gaskets made of rubber or metal, reinforced graphite gaskets provide a superior seal that can handle extreme conditions. The main benefit of using reinforced graphite lies in its ability to combine flexibility with strength. The material’s ability to compress and adapt to uneven sealing surfaces ensures a tight seal, even under high-pressure conditions.

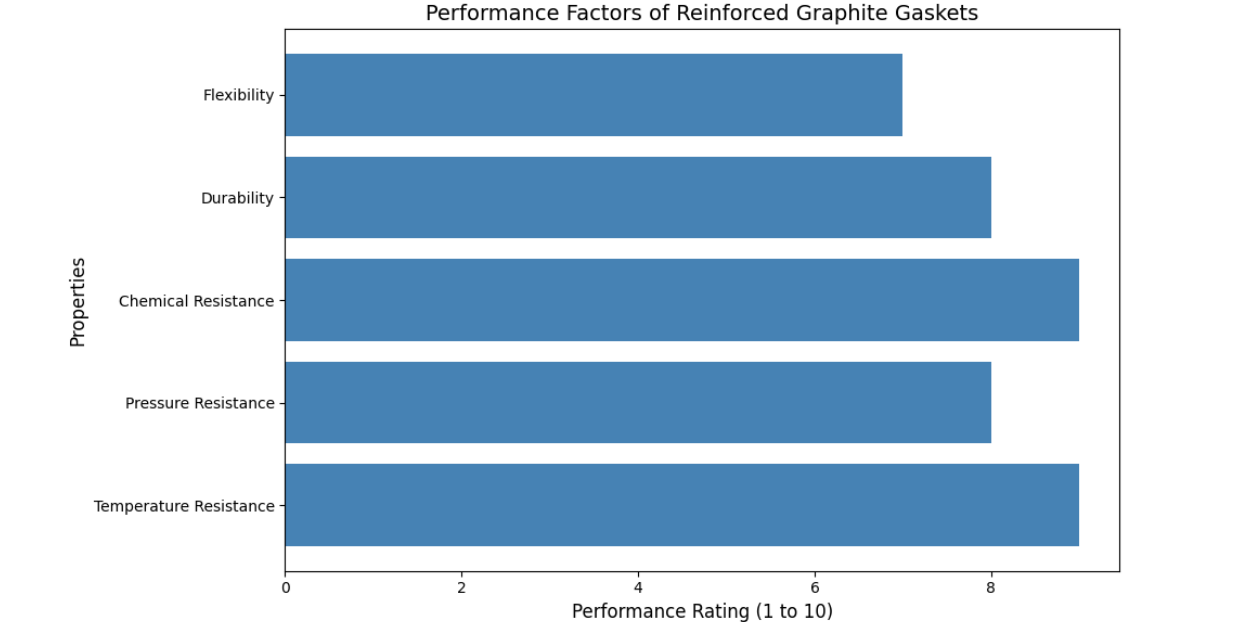

Reinforced graphite gaskets stand out due to their unique combination of high-temperature resistance, chemical resistance, mechanical strength, and flexibility. These gaskets can perform effectively in temperatures ranging from -240°C to +550°C, making them ideal for environments that experience drastic temperature fluctuations.

One of the most notable properties of reinforced graphite gaskets is their excellent thermal shock resistance. Graphite, as a material, can handle rapid temperature changes without cracking or losing its sealing properties. This is especially crucial in industries where equipment is exposed to frequent and significant thermal cycling.

The gasket's chemical resistance is also a significant advantage. Graphite’s natural inertness makes it highly resistant to a wide range of chemicals, including acids, solvents, and alkalis. This resistance allows reinforced graphite gaskets to maintain their sealing integrity even in aggressive environments, such as chemical plants or refineries.

Additionally, reinforced graphite gaskets exhibit low creep and relaxation under pressure, which ensures long-term sealing performance. The gasket’s ability to maintain its shape and seal under pressure over time helps prevent leaks and maintain system efficiency.

Graphite’s ability to absorb thermal shocks without cracking or deforming is a crucial factor in high-temperature applications. This characteristic ensures that the gasket can maintain a reliable seal despite rapid changes in temperature, making it ideal for industries where equipment faces extreme and sudden thermal shifts.

Reinforced graphite’s resistance to oxidation and chemical degradation is a key feature that enhances its longevity and reliability. This property allows the gasket to be used in harsh chemical environments where other materials might degrade, ensuring the continued performance of the sealing system.

The ability of reinforced graphite gaskets to recover their original shape after compression ensures a tight seal over extended periods. This feature is particularly important in high-pressure systems, where the gasket must maintain its sealing capabilities under constant compression.

Property | Description |

High Temperature Resistance | Can withstand temperatures from -240°C to +550°C, making them ideal for extreme heat conditions. |

Chemical Resistance | Resistant to aggressive chemicals, including acids, alkalis, and solvents. |

Mechanical Strength | Maintains strength under high pressure and adapts to flange irregularities. |

Low Creep and Relaxation | Ensures long-term sealing without degradation under constant pressure. |

Thermal Shock Resistance | Can endure rapid temperature changes without cracking or loss of sealing performance. |

Reinforced graphite gaskets are widely used in a range of industries, thanks to their durability, reliability, and versatility. In the oil and gas industry, they are essential for sealing pipelines, drilling systems, and processing equipment, where both high temperature and pressure are prevalent.

In power generation, reinforced graphite gaskets are used to seal steam turbines, boilers, and heat exchangers. Their ability to withstand extreme heat and pressure makes them ideal for these critical applications, where seal integrity is paramount.

Chemical processing plants, refineries, and reactors also rely on reinforced graphite gaskets for sealing purposes. These gaskets provide reliable sealing even when exposed to aggressive chemicals and high temperatures, which is essential for maintaining the safety and efficiency of these facilities.

Aerospace and automotive industries also benefit from the use of reinforced graphite gaskets. In aerospace, they are used in high-pressure and high-temperature systems, while in automotive applications, they are commonly found in exhaust systems and engine components, where they ensure tight seals under extreme conditions.

Reinforced graphite gaskets are particularly well-suited for high-pressure systems that exceed 200 bar. Their mechanical strength and ability to withstand intense pressure make them indispensable in sealing applications where other materials might fail under stress.

Reinforced graphite gaskets excel in high-temperature systems, where other gasket materials may deteriorate. The ability of graphite to maintain its structural integrity at temperatures of up to 550°C ensures that it remains effective in environments exposed to continuous heat.

Reinforced graphite gaskets come in various forms, each designed for specific applications. Pure graphite gaskets offer basic sealing capabilities, while graphite gaskets with metal inserts enhance the material’s strength and durability, making them suitable for high-pressure and high-temperature applications.

Graphite with stainless steel inserts provides additional resistance to pressure and temperature, making them ideal for more demanding industrial applications. Spiral-wound graphite gaskets, which combine graphite and metal, offer added flexibility and strength, ensuring a reliable seal under fluctuating pressures and temperatures.

Tanged graphite gaskets are reinforced with a perforated metal tang, which provides additional mechanical strength and pressure resistance. These gaskets are often used in high-pressure environments where enhanced sealing capabilities are needed.

Expanded graphite gaskets are characterized by their porous structure, which allows for increased flexibility. These gaskets are ideal for applications that experience fluctuating pressures and temperatures, as they can adapt to changes in the system without losing their sealing properties.

The addition of wire mesh reinforcement increases the strength and durability of the gasket. This makes it suitable for use in extreme conditions, where additional support is required to maintain seal integrity under pressure.

Type | Description | Best Use Cases |

Pure Graphite Gaskets | Made of 100% graphite, used for general sealing needs. | Standard sealing applications across industries. |

Graphite with Metal Inserts | Graphite gaskets with metal reinforcement to improve mechanical strength. | High-pressure and high-temperature applications. |

Graphite with Stainless Steel Insert | Provides added resistance to pressure and heat, ideal for tough sealing environments. | Sealing in high-temperature steam and pressure systems. |

Spiral-Wound Graphite Gaskets | Combines graphite and metal for enhanced flexibility and strength. | Ideal for flange connections in high-pressure systems. |

Tanged Graphite Gaskets | Reinforced with a perforated metal tang for added strength and pressure resistance. | Applications in high-pressure systems. |

Expanded Graphite Gaskets | Uses expanded graphite for better adaptability in fluctuating pressures and temperatures. | Applications with varying temperature and pressure. |

Reinforced Graphite with Wire Mesh | Combines wire mesh for additional strength in extreme conditions. | Used in highly demanding environments with severe pressure. |

The advantages of reinforced graphite gaskets make them an excellent choice for a wide variety of industrial applications. Their long-term durability reduces the need for frequent replacements, making them a cost-effective solution in the long run.

The versatility of reinforced graphite gaskets means they can be used in a range of industries, from oil and gas to power generation and aerospace. Their resistance to heat, pressure, and chemicals makes them indispensable in demanding environments.

Reinforced graphite gaskets also contribute to improved operational efficiency. By maintaining a reliable seal, they prevent leaks and minimize downtime, which leads to more efficient system performance.

By preventing hazardous leaks in high-pressure systems, reinforced graphite gaskets play a crucial role in enhancing safety. Their ability to maintain a reliable seal ensures that systems operate safely, even in the most demanding conditions.

Reinforced graphite gaskets contribute to improved operational efficiency by reducing the likelihood of leaks and ensuring that systems remain sealed over time. This reduces maintenance costs and increases the overall reliability of industrial systems.

When selecting a reinforced graphite gasket, it’s important to consider the specific temperature and pressure conditions of your application. Gaskets with metal inserts or additional reinforcement may be required for higher-pressure systems, while pure graphite gaskets may be suitable for less demanding environments.

Material considerations, such as the type of metal insert (e.g., stainless steel, nickel) and the need for wire mesh reinforcement, will also influence gasket performance. Custom-cut gaskets are available to fit unique flange designs, ensuring a perfect seal for any application.

It’s important to select reinforced graphite gaskets that meet relevant industry standards, such as ASME, DIN, and EN. These standards ensure that the gaskets are manufactured to the highest quality and can handle the demands of your specific application.

Many manufacturers offer customized reinforced graphite gaskets to meet the specific needs of your application. Customization ensures that the gasket fits perfectly, offering optimal sealing performance and longevity.

Reinforced graphite gaskets combine exceptional properties, making them perfect for high-temperature and high-pressure applications. Their durability, chemical resistance, and long-lasting performance make them valuable in various industries. By choosing the right reinforced graphite gasket, industries can boost efficiency, reduce maintenance costs, and improve safety and performance. Ningbo Dongheng Sealing Co., Ltd. offers reliable sealing solutions with reinforced graphite gaskets, ensuring optimal performance in demanding environments.

A: A reinforced graphite gasket is a sealing material designed for high-temperature and high-pressure applications. It combines graphite with metal or other reinforcements to enhance its strength and sealing capabilities.

A: Reinforced graphite gaskets are ideal for these environments because they withstand extreme temperatures and pressures while maintaining excellent sealing properties, ensuring system reliability.

A: Reinforced graphite gaskets offer exceptional chemical resistance, making them suitable for sealing in environments with aggressive chemicals, acids, and solvents.

A: Reinforced graphite gaskets are commonly used in industries like oil and gas, power generation, chemical processing, aerospace, and automotive for their ability to handle extreme conditions.

A: These gaskets reduce the risk of leaks, ensuring tight seals under high pressure and temperature, which in turn minimizes downtime, maintenance, and operational inefficiencies.

Address